With two decades of experience in producing shearing machines, our product line includes NC shearing machine , CNC shearing machine, robotic shearing machine, large shearing machine, and more, enabling us to meet your diverse sheet metal bending requirements.

Stat title

Stat title

Stat title

Stat title

QC12K-Series NC Hydraulic Shearing Machine

1. Standard Facilities:

1). ESTUN E21S NC control + Frequency inverter control back gauge and shearing times

2). Front support arms with stopper and measure scale

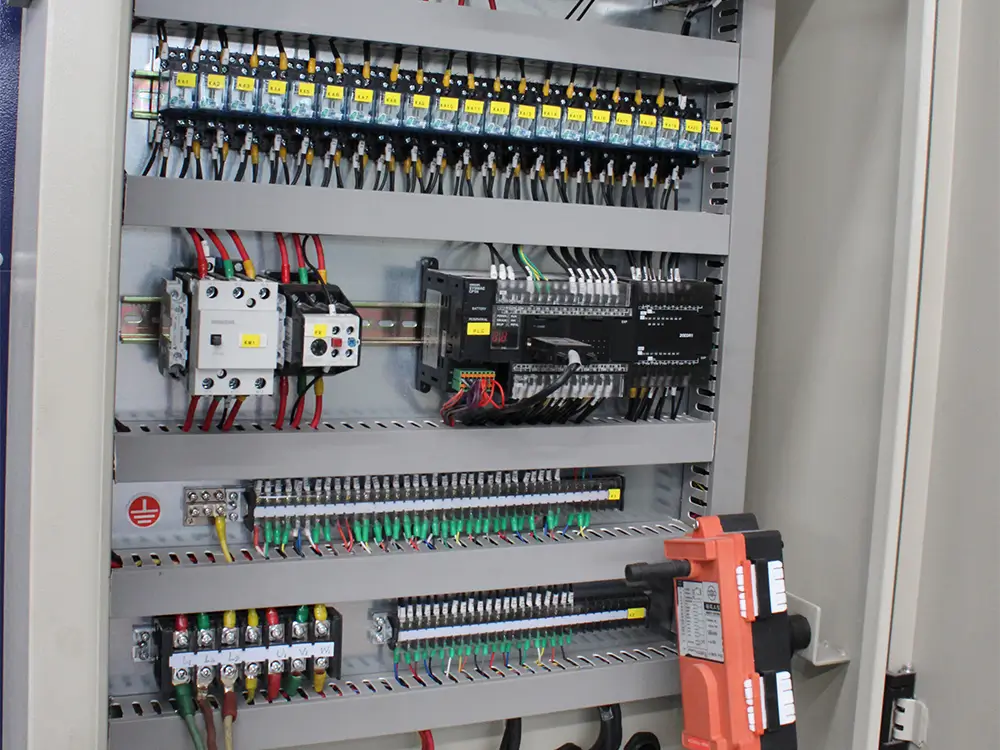

3). Main electric components are from Siemens or Schneider.

4). Hydraulic seals are from NOK, Japan

5). Hydraulic valves are from Germany Rexroth

6). Hydraulic pump is from SUNNY brand (USA venture in China )

7). Ball screw & Line guide rail Taiwan HIWIN

8). Steel-welded construction, vibration to eliminate stress, with high strength and good rigidity

9). Hydraulic top-drive, steadiness and reliability

10). With adopts quick manual adjust device, cutting stroke can adjust to be suitable shearing short sheet

11). With motor-driven back gauge and counter device

12). CE standard front light curtain and back-safety curtain

2.Control System

NC Controller: ESTUN E21S & E200S controller

CNC Controller: DAC310, DAC360 DELEM Holland.

3. After-Sale Services

1). Free installation, trial start and adjustment, training. Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

2). Warranty period is 2 years. During the warranty period we shall reply to the call or Fax from the user for the machine faults (expect for faults caused by no abiding by the relevant operation regulations, or by force injury) within 24 hours.

3). We arrange final test before shipment. We run the machine for a few days, and then use customer’s materials for test. After making sure machine is the best performance, then make shipments.

4. Main functions:

1). The machine frame is welded construction with steel plate, and stress is eliminated by vibration. With high strength, stable performance, easy operation and convenient maintenance.

2). As the cutting beam of machine has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

3). With the help of hydraulic drive, swing beam, return of knife beam is smooth and prompt by accumulator (Nitrogen cylinder but we can make hydraulic return).

4). Stepless adjusting is available for the stroke of knife beam for different length plate shearing.

5). The position of low blade is adjustable, thus ensuring the equilibrium of the gap between blades after regrinding.

6). It is easy and quick to adjust the gap between blades. The value of the gap is indicated on a dial.

7). Motorized adjusting and manual adjusting for the back gauge (take up the back-gauge system, cutting plate without back gauge).

Main Components

1). Hydraulic system: Bosch Rexroth

2). Electro parts: Siemens Germany/Schneider France

3). Ball screw: Taiwan HIWIN

4). Line guide rail: Taiwan HIWIN

5). Oil Sealing: Valqua Japan

Technical Parameters:

| Model | Mild steel (450MPa) | Cutting length (mm) | Shear angle | Travel time | Back gauge range (mm) | Main motor (kw) | Weight (kg) | LxWxH (mm) |

| 4×2500 | 4 | 2500 | 1º30´ | 16 | 20~500 | 5.5 | 3600 | 3040X1550X1550 |

| 4×3200 | 4 | 3200 | 1º30´ | 13 | 20~500 | 5.5 | 4500 | 3840X1550X1550 |

| 4×4000 | 4 | 4000 | 1º30´ | 10 | 20~600 | 5.5 | 6500 | 4600X1700X1700 |

| 6×2500 | 6 | 2500 | 1º30´ | 15 | 20~500 | 7.5 | 5000 | 3040X1710X1620 |

| 6×3200 | 6 | 3200 | 1º30´ | 12 | 20~500 | 7.5 | 5800 | 3840X1850X1620 |

| 6×4000 | 6 | 4000 | 1º30´ | 9 | 20~600 | 7.5 | 8200 | 4620X1850X1700 |

| 6×5000 | 6 | 5000 | 1º30´ | 8 | 20~600 | 7.5 | 10500 | 5400X1850X1700 |

| 6×6000 | 6 | 6000 | 1º30´ | 5 | 20~800 | 11 | 14000 | 6480X2100X2300 |

| 8×2500 | 8 | 2500 | 1º30´ | 11 | 20~500 | 7.5 | 5500 | 3040X1700X1700 |

| 8×3200 | 8 | 3200 | 1º30´ | 8 | 20~500 | 7.5 | 6300 | 3860X1700X1700 |

| 8×4000 | 8 | 4000 | 1º30´ | 8 | 20~600 | 7.5 | 8200 | 4640X1700X1700 |

| 8×5000 | 8 | 5000 | 1º30´ | 8 | 20~600 | 7.5 | 11500 | 5400X2400X2000 |

| 8×6000 | 8 | 6000 | 1º30´ | 8 | 20~800 | 11 | 20000 | 6480X2100X2350 |

| 10×2500 | 10 | 2500 | 1º30´ | 10 | 20~500 | 11 | 7200 | 3040X1800X1700 |

| 10×3200 | 10 | 3200 | 1º30´ | 10 | 20~500 | 11 | 8000 | 3860X2000X1700 |

| 10×4000 | 10 | 4000 | 1º30´ | 10 | 20~600 | 11 | 12050 | 4650X2100X2000 |

| 10×6000 | 10 | 6000 | 1º30´ | 10 | 20~800 | 15 | 24000 | 6500X2100X2300 |

| 12×2500 | 12 | 2500 | 2º | 12 | 20~600 | 18.5 | 9000 | 3140X2050X2000 |

| 12×3200 | 12 | 3200 | 2º | 10 | 20~600 | 18.5 | 10500 | 3880X2150X2000 |

| 12×4000 | 12 | 4000 | 2º | 10 | 20~600 | 18.5 | 14800 | 4680X2150X2100 |

| 12×6000 | 12 | 6000 | 2º | 5 | 20~1000 | 18.5 | 26000 | 6900X2600X2700 |

| 16×2500 | 16 | 2500 | 2º30´ | 10 | 20~600 | 18.5 | 11000 | 3140X2150X2000 |

| 16×3200 | 16 | 3200 | 2º30´ | 10 | 20~600 | 18.5 | 14000 | 3880X2150X2000 |

| 16×4000 | 16 | 4000 | 2º30´ | 10 | 20~800 | 18.5 | 16000 | 4650X2150X2200 |

| 16×6000 | 16 | 6000 | 2º | 5 | 20~1000 | 22 | 32000 | 6900X2700X2700 |

| 20×2500 | 20 | 2500 | 3º | 8 | 20~800 | 22 | 17000 | 3440X2300X2500 |

| 20×3200 | 20 | 3200 | 3º | 8 | 20~800 | 22 | 20000 | 4150X2350X2700 |

| 20×4000 | 20 | 4000 | 3º | 5 | 20~1000 | 22 | 22000 | 4850X2600X2400 |

| 20×6000 | 20 | 6000 | 3º | 4 | 20~1000 | 22 | 47000 | 6700X3000X3000 |

| 25×2500 | 25 | 2500 | 3º | 8 | 20~1000 | 37 | 20000 | 3200X2700X2900 |

| 25×3200 | 25 | 3200 | 3º | 5 | 20~1000 | 37 | 24000 | 4200X2400X2500 |

| 30×2500 | 30 | 2500 | 3º | 4 | 20~1000 | 37 | 28000 | 3300X2900X3000 |

| 30×3200 | 30 | 3200 | 3º30´ | 4 | 20~1000 | 40 | 34000 | 4200X2500X2600 |

| 40×2500 | 40 | 2500 | 4º | 3 | 20~1000 | 75 | 46000 | 3200X3300X3200 |

| 40×3200 | 40 | 3200 | 4º | 3 | 20~1000 | 90 | 58000 | 4300X3300X3000 |