CNC Press Brake

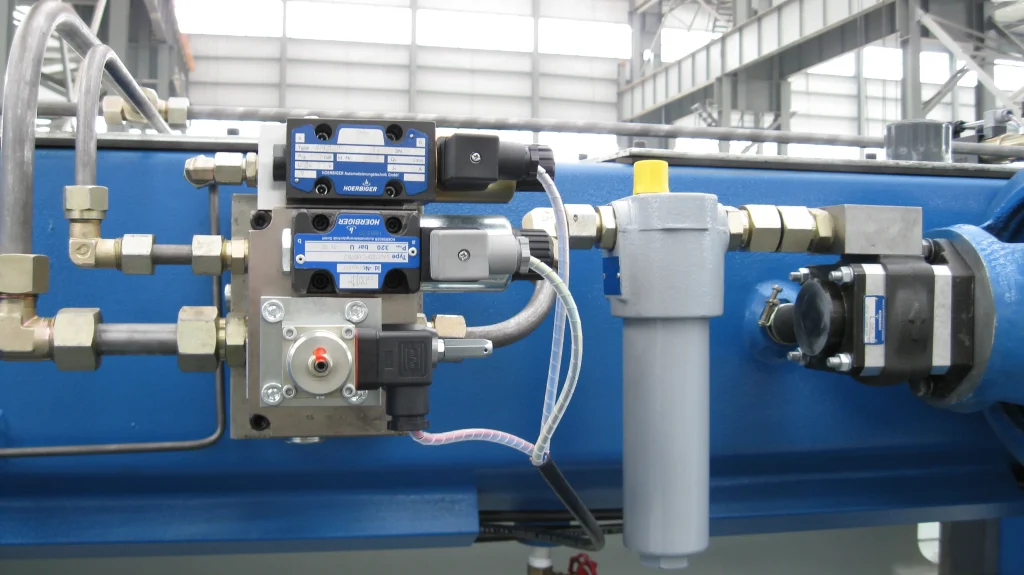

Hydraulic System

Working Table Crowning System

The servo Crowning system repeatable crowning that is precisely adjusted by a basic hand crank and digital readout or an electric motor driven by the CNC control system

Laser Safe Optical Safety Guards

Quickly Clamp System

WILA Hydraulic Clamp System

CNC Control System

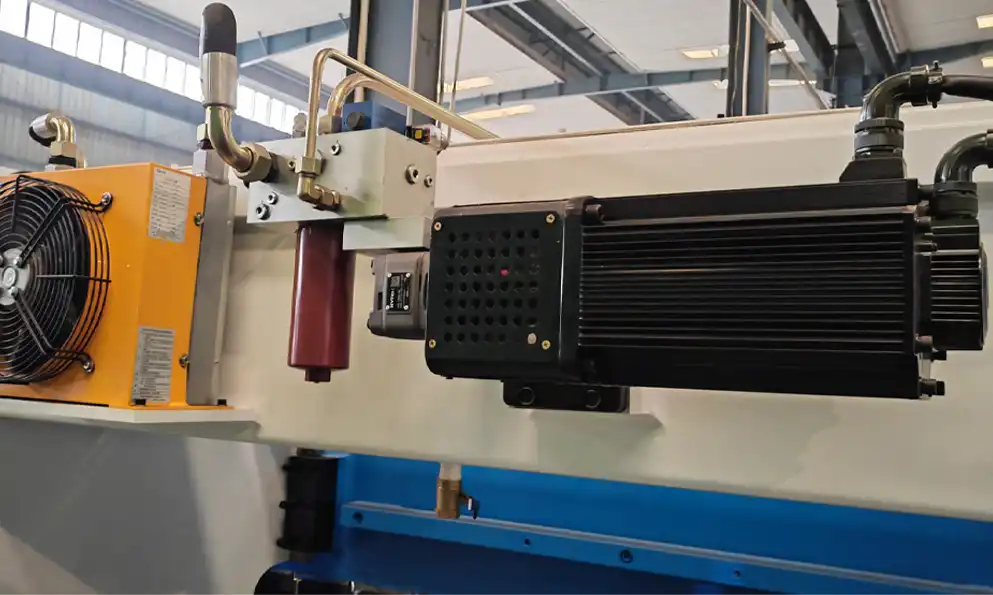

Hybrid Servo ECO system & Hydraulic oil Cooling system

More Detail

CNC Control system

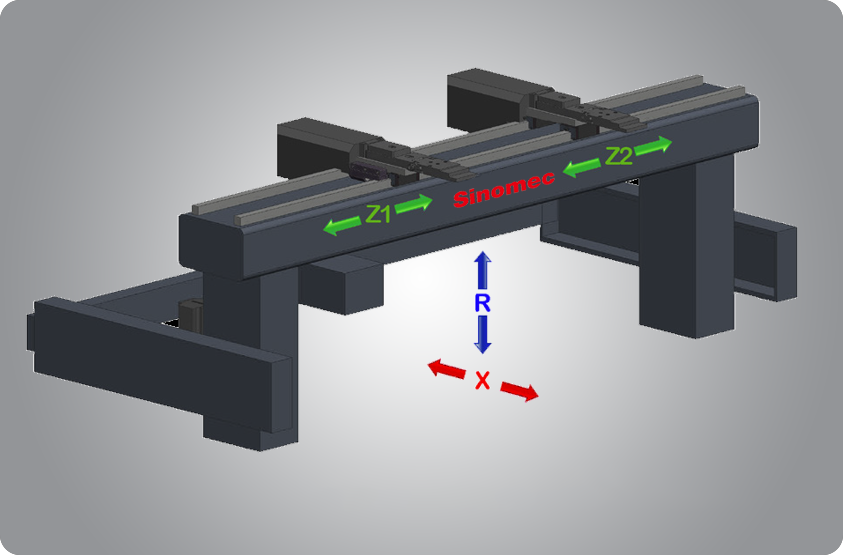

Smart Back Gauge

CNC Bending Follower Support

LaserCheck Bending Angle

Technical Parameters

| Model | 40T/2500 | 50T/2500 | 63T/2500 | 80T/2500 | 80T/3200 | 80T/4000 | 100T/3200 | 100T/4000 | 125T/3200 | 125T/4000 |

| Bending Force (KN) | 400 | 500 | 630 | 800 | 800 | 800 | 1000 | 1000 | 1250 | 1250 |

| Bending Length (mm) | 2500 | 2500 | 2500 | 2500 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 |

| Vertical Distance (mm) | 1900 | 1900 | 1900 | 1900 | 2700 | 3500 | 2700 | 3500 | 2700 | 3500 |

| Throat Depth (mm) | 300 | 300 | 350 | 350 | 350 | 350 | 400 | 400 | 400 | 400 |

| Stroke (mm) | 150 | 150 | 170 | 170 | 170 | 170 | 200 | 200 | 200 | 200 |

| Worktable Height (mm) | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Worktable Width (mm) | 320 | 350 | 380 | 380 | 380 | 380 | 420 | 420 | 420 | 420 |

| Quick down speed (mm/s) | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Return Speed (mm/s) | 100 | 100 | 100 | 110 | 110 | 110 | 100 | 100 | 100 | 100 |

| Working speed (mm/s) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Back gauge stroke (mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Back gauge speed (mm/s) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Main power (Kw) | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| No. of Axis (4+1) | Y1, Y2, X, R+W (Hydraulic Crowning System) | |||||||||

| Weight(Approx.) (Tons) | 3.5 | 4.5 | 5.8 | 7 | 7.8 | 8.5 | 8.5 | 9.5 | 9 | 9.8 |

| Model | 160T/3200 | 160T/4000 | 160T/6000 | 200T/3200 | 200T/4000 | 300T/3200 | 300T/4000 | 400T/4000 | 400T/6000 | 500T/6000 |

| Bending Force (KN) | 1600 | 1600 | 1600 | 2000 | 2000 | 3000 | 3000 | 4000 | 4000 | 5000 |

| Bending Length (mm) | 3200 | 4000 | 6000 | 3200 | 4000 | 3200 | 4000 | 4000 | 6000 | 6000 |

| Vertical Distance (mm) | 2700 | 3500 | 4900 | 2700 | 3500 | 2700 | 3500 | 3500 | 4900 | 4900 |

| Throat Depth (mm) | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 500 |

| Stroke (mm) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 320 |

| Worktable Height (mm) | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Worktable Width (mm) | 80 | 80 | 80 | 100 | 100 | 100 | 100 | 110 | 110 | 300 |

| Quick down speed (mm/s) | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 110 | 110 | 85 |

| Return Speed (mm/s) | 100 | 100 | 100 | 100 | 100 | 110 | 110 | 80 | 80 | 75 |

| Working speed (mm/s) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 8 |

| Back gauge stroke (mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Back gauge speed (mm/s) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Main power (Kw) | 11 | 11 | 15 | 15 | 15 | 18.5 | 18.5 | 22.5 | 30 | 37 |

| No. of Axis (4+1) | Y1, Y2, X, R+W (Hydraulic Crowning System) | |||||||||

| Weight(Approx.) (Tons) | 11 | 12 | 19.5 | 14.2 | 15.5 | 16.8 | 18 | 31 | 35 | 53 |

More Machine

Laser Cutting

CNC Press Brake

CNC Shearing

4-roll Rolling

Cut Length Line

Contact Us

Not sure which machine is right for your sheet metal product?Let our knowledgeable sales team guide you in selecting the most suitable solution for your needs.